Model 2596 10-60 Inch Automatic Self-Cleaning Basket Strainer

Carbon Steel, Flanged, Screwed, or Socket Weld, 10" to 60"The Eaton Model 2596 10" to 60" Automatic Self-cleaning Strainer is designed for the continuous removal of particle solids from liquids in pipeline systems, preventing damage to expensive pipeline system components. It features the unique idL™ shaft seal that positively prevents leakage from the backwash shaft at the top of the strainer.

-

Features:

- Flow rates up to 35,000 gpm (7949 m3/hr)

- A broad selection of screen options

- Exclusive idL™ Seal for leak free service, available up to 24" only

- Automatic backwashing for operator-free service and minimal backwash effluent

- Fabricated carbon steel construction

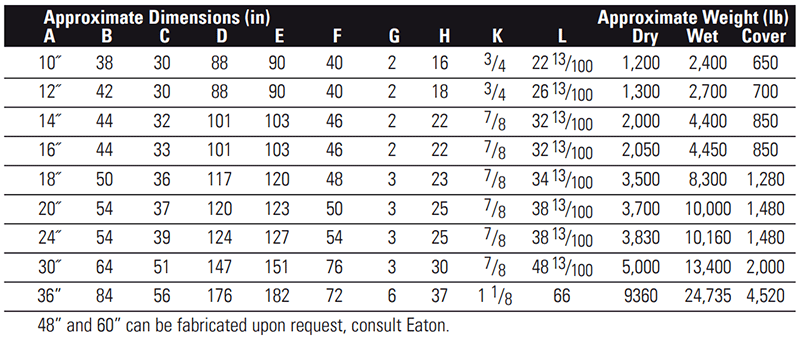

Available Sizes: 10", 12", 14", 16", 18", 20", 24", 30", 36", 48", and 60"

48” and 60” can be fabricated upon request, consult mdi.

48” and 60” can be fabricated upon request, consult mdi.

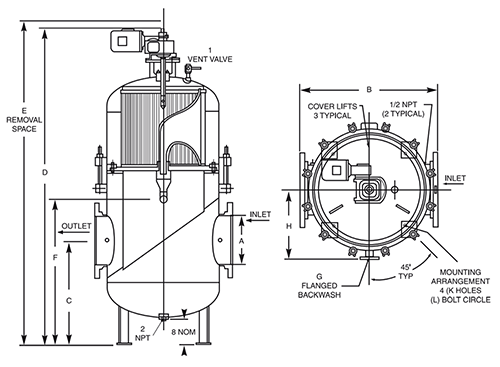

To simplify maintenance the Model 2596 features a unitized modular assembly. The motor, gear reducer, and the internal operating mechanism are housed within the strainer cover and lift off as a unit. This makes all components easily accessible and reduces associated maintenance costs.

With an automatic control system monitoring the strainer operation, cleaning is accomplished by an integral backwash system. A small portion of the screen element is isolated and cleaned by reverse flow. The remaining screen area continues to strain – providing uninterrupted flow. With this efficient design, only a small amount of the liquid being strained is used to carry away the debris from the strainer. Continuous flow is assured and protection is provided for nozzles, pumps, valves, heat exchangers, and process equipment.

Application Limits

• Fabricated strainers are designed within the limits of the customer’s specifications and design criteria along with any applicable code requirement, i.e. ASME Section VIII Div. 1.

With an automatic control system monitoring the strainer operation, cleaning is accomplished by an integral backwash system. A small portion of the screen element is isolated and cleaned by reverse flow. The remaining screen area continues to strain – providing uninterrupted flow. With this efficient design, only a small amount of the liquid being strained is used to carry away the debris from the strainer. Continuous flow is assured and protection is provided for nozzles, pumps, valves, heat exchangers, and process equipment.

Application Limits

• Fabricated strainers are designed within the limits of the customer’s specifications and design criteria along with any applicable code requirement, i.e. ASME Section VIII Div. 1.

Model 2596 Automatic Control Systems

Eaton Automatic Control Systems (ACS) are specifically designed to monitor and operate the backwash cleaning system of Eaton Models 2596 Automatic Strainers.

Click Here to View the Available Automatic Control Systems

Options

• Various grades of stainless steel, copper nickel, monel, and other exotic materials of construction

• ASME Section VIII, Div. 1. code stamp available

• Flanged, screwed, or socket weld backwash connections

• Internal and external epoxy paint or other coatings, upon request, on all carbon steel components for fresh water service applications

• Custom designs are available upon request

Eaton Automatic Control Systems (ACS) are specifically designed to monitor and operate the backwash cleaning system of Eaton Models 2596 Automatic Strainers.

Click Here to View the Available Automatic Control Systems

Options

• Various grades of stainless steel, copper nickel, monel, and other exotic materials of construction

• ASME Section VIII, Div. 1. code stamp available

• Flanged, screwed, or socket weld backwash connections

• Internal and external epoxy paint or other coatings, upon request, on all carbon steel components for fresh water service applications

• Custom designs are available upon request

- Model 2596 10-60 Inch Automatic Self-Cleaning Basket Strainer Data Sheet

- Model 2596 Control Systems

- Model 2596 Automatic Self-Cleaning Basket Strainer Technical Data

- Eaton Automatic Self-Cleaning Pipeline Strainers Catalog

- Eaton Model 2596 Automatic Self-Cleaning Strainers - How It Works

- Model 2596 Control Systems Installation, Operation & Maintenance Manual

- Eaton Manual-Automatic Pipeline Strainers Catalog

- Eaton Basket and Screen Data

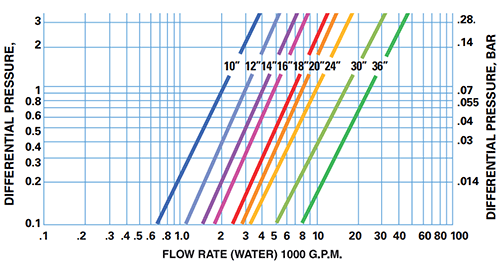

- Pressure Drop Calculations

Click for Larger View

Click for Larger View Flow Rates - Click for Larger View

Flow Rates - Click for Larger View Click for Larger View

Click for Larger View Flow Rates - Click for Larger View

Flow Rates - Click for Larger View