Click for Larger View

Click for Larger View Shown In Stainless Steel

Shown In Stainless SteelClick for Larger View

Call us TODAY at 727-835-0665 or

Toll Free at 800-761-4298

Request A Quote!

Model 53BTX Duplex Basket Strainer

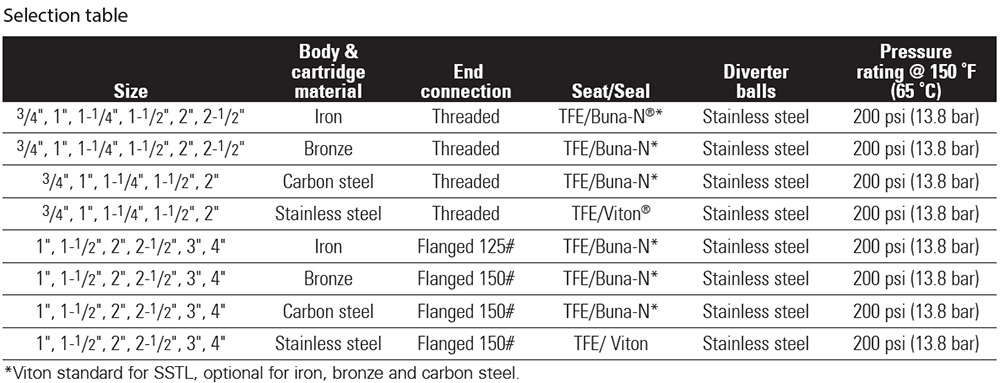

Iron, Bronze, Carbon Steel or Stainless Steel, Threaded or Flanged, 3/4" to 4"The Model 53BTX Duplex Strainer will give years of trouble-free service, protecting expensive pipeline system components from damage by unwanted particles. Because the system flow never has to be shut down for basket cleaning, the Model 53BTX duplex strainer is perfect for lines that must run continuously or for batch systems that can't be stopped. Draining this chamber is easy; the cover lifts and swings clear of the chamber opening with no special tools required.

-

Features:

- Dynamic sealing design for long life

- Easy-to-operate lever handle—no gear box required

- Unique seat and seal design requires no adjustments

- Teflon® seats for longer service life

- Foot pads for rock solid installation

- Double-stem O-rings for positive sealing

- Easy to access body vent valve

- Drain plugs in each basket cover

- Piston seal strainer basket cover

- Easy access for diverter cartridge removal

- 316 stainless steel ball design

Available Sizes:

3/4", 1", 1-1/4", 1-1/2", 2", 2-1/2", 3", 4"

No-Hassle Strainer Basket Servicing

The Model 53BTX features a design that makes strainer basket servicing a no-hassle operation. No more "race against the clock" during basket servicing to get the job done before the basket chamber overflows with fluid. The Model 53BTX keeps the chamber dry during service. This gives you time to clean or replace the strainer basket without ever having to worry about leakage and overflow. And...without overflow, there is no need to clean up after servicing the strainer basket. The Model 53BTX is simply a better way to work.

A Better Duplex Strainer Design

A unique flow diverter valve cartridge in the Model 53BTX isolates the two strainer basket chambers and prevents fluid by-pass. An easy-to-turn handle operates the cartridge and diverts the system flow from one chamber to the other, the flow in the pipeline is never shut off, perfect for batch or continuous process applications. When a strainer basket needs to be cleaned, the lever handle is turned to take the basket out of service and to divert the flow through the other chamber. The position of the handle clearly indicates at all times which chamber is in service. No special tools are needed to access the strainer basket for cleaning. The chamber is first drained and then the cover is lifted and swung clear of the chamber opening. The dynamic diverter cartridge seals prevent fluid by-pass into the out-of-service chamber, making for easy, hassle-free strainer basket servicing.

A Better Flow Diverter Cartridge

The heart of the Model 53BTX Duplex Strainer is the unique flow diverter cartridge that features a highly dynamic sealing system on the diverter balls that ensures exceptionally long life and positive sealing. The design works so well that there is no need for manual internal or external ball support adjustment, and the low operating torque means the strainer can be operated with an easy-turn lever handle, a gear box is not needed. A double sealing system on both the upper and lower stems guards against any possible leakage. Special reinforced polymer seats are used for extended service life. Should cartridge service become necessary, it's easy to accomplish. Just remove four bolts and the cartridge comes right out through the top of the strainer. There is no need to take the strainer completely apart or to remove it from the line.

The Model 53BTX features a design that makes strainer basket servicing a no-hassle operation. No more "race against the clock" during basket servicing to get the job done before the basket chamber overflows with fluid. The Model 53BTX keeps the chamber dry during service. This gives you time to clean or replace the strainer basket without ever having to worry about leakage and overflow. And...without overflow, there is no need to clean up after servicing the strainer basket. The Model 53BTX is simply a better way to work.

A Better Duplex Strainer Design

A unique flow diverter valve cartridge in the Model 53BTX isolates the two strainer basket chambers and prevents fluid by-pass. An easy-to-turn handle operates the cartridge and diverts the system flow from one chamber to the other, the flow in the pipeline is never shut off, perfect for batch or continuous process applications. When a strainer basket needs to be cleaned, the lever handle is turned to take the basket out of service and to divert the flow through the other chamber. The position of the handle clearly indicates at all times which chamber is in service. No special tools are needed to access the strainer basket for cleaning. The chamber is first drained and then the cover is lifted and swung clear of the chamber opening. The dynamic diverter cartridge seals prevent fluid by-pass into the out-of-service chamber, making for easy, hassle-free strainer basket servicing.

A Better Flow Diverter Cartridge

The heart of the Model 53BTX Duplex Strainer is the unique flow diverter cartridge that features a highly dynamic sealing system on the diverter balls that ensures exceptionally long life and positive sealing. The design works so well that there is no need for manual internal or external ball support adjustment, and the low operating torque means the strainer can be operated with an easy-turn lever handle, a gear box is not needed. A double sealing system on both the upper and lower stems guards against any possible leakage. Special reinforced polymer seats are used for extended service life. Should cartridge service become necessary, it's easy to accomplish. Just remove four bolts and the cartridge comes right out through the top of the strainer. There is no need to take the strainer completely apart or to remove it from the line.

Options and Temporary Strainers

Options and Temporary Strainers

Offered in pipeline sizes from 3/4" to 4", the Model 53BTX can be supplied with threaded or flanged pipe connections. Stainless steel strainer baskets with a low-pressure drop design are standard - and you can choose perforations/mesh sizes from 1/2" down to 400 microns. Special alloy baskets are available as an option - as are differential pressure gauges and switches, magnetic separators, drain valves, a basket chamber vent and a pressure equalizing assembly.

Flow Rates - Click for Larger View

Flow Rates - Click for Larger View Click for Larger View

Click for Larger View Click for Larger View

Click for Larger View Click for Larger View

Click for Larger View